CHETO CATALOG (EN)

File typepdf

Size1.92 MB

Download

See online

Fill in the fields correctly

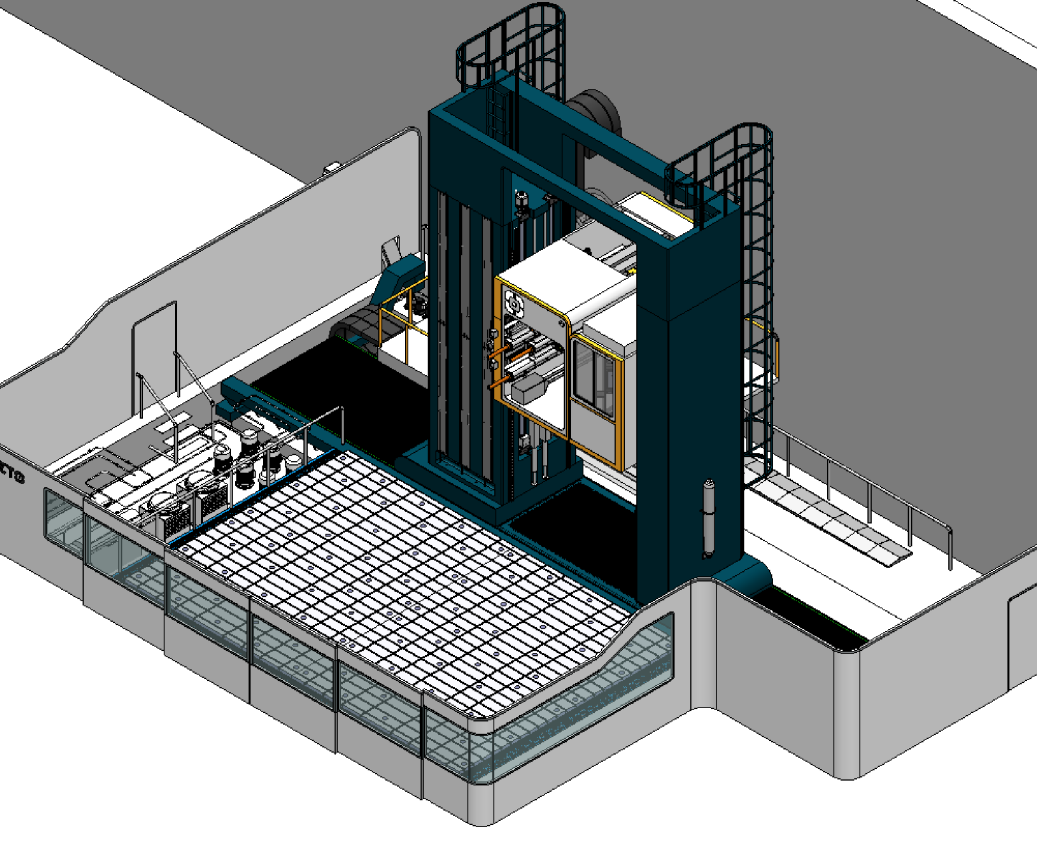

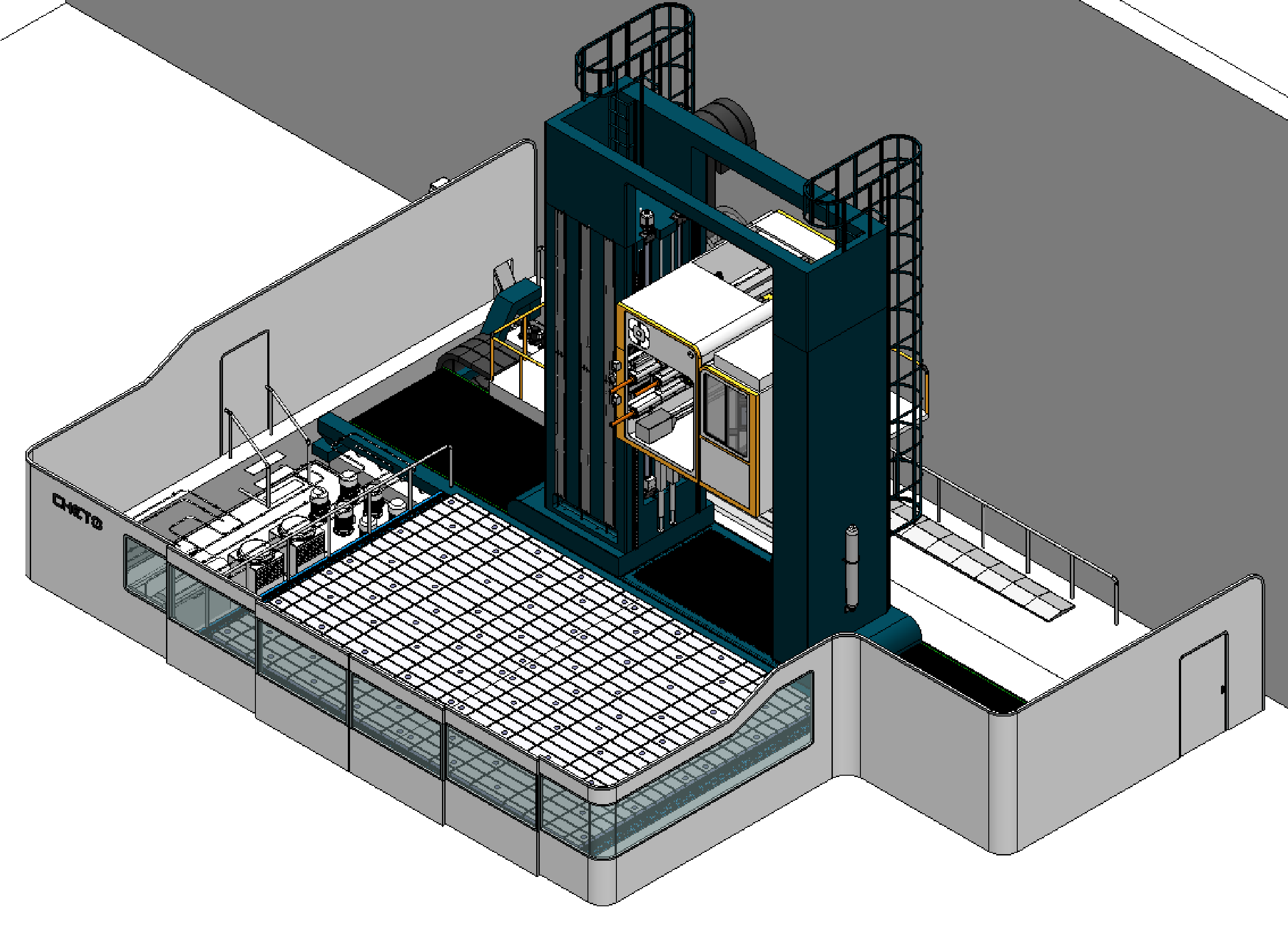

CNC DEEP HOLE DRILLING WITH MILLING

GPS. 40°48'00.5

+351 256 247 970